Performance is our concern

Werkzeugkonzepte

Wir entwickeln die passende Konfiguration für das erforderliche Konzept

Kontaktieren Sie uns

Toolmaking

We turn your developments into reality. Qualified employees design tools and devices of all kinds on modern CAD workstations.

We know what is important in stamping and forming technology and support our customers from product development to prototypes to the finished component. We develop, design and build the resulting sophisticated tools for use in the customer’s own production facility or in our stamped part production, depending on the customer’s specifications. If there are no customer specifications, we manufacture the stamping tools that remain at Baier in accordance with our internal guidelines.

The function of the end product determines every phase of mould development. Your ideas and our ideas work together in the planning phase to achieve optimum function. The result is innovative and technically sophisticated designs.

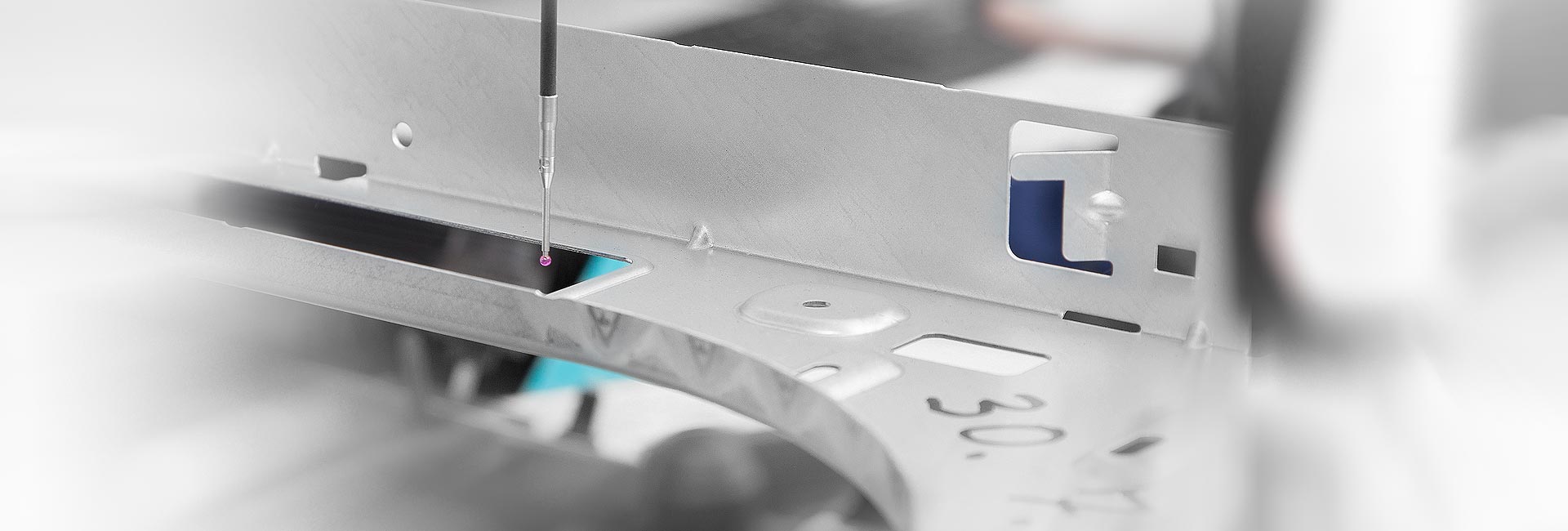

Based on these plans, our toolmakers manufacture high-precision individual parts from which the tools are created. The finishing touches are provided by the expertise and sensitivity of our fitters and the adjustment of the tools under series production conditions. The extensive machinery of our punched part production is available for this purpose. The results are checked using our modern measurement technology.

We manufacture

- Punching and forming tools in progressive die technology (progressive tools, levelling tools, embossing tools and drawing tools) including the integration of additional operations such as feeding and caulking of studs or threaded bolts or the forming of threads in the tool

- Insertion tools

- Prototypes

- Tool sizes up to 4,000 mm in length, also in modular design

- Devices

- Contract manufacturing in toolmaking on request

DEVELOPMENT

Knowing what matters

“It always starts with an idea.”

Our tool designers follow your ideas and develop them further to create the right product drawing for your order and ultimately the right tool for your production.

Our decades of experience and the associated technological expertise enable us to provide our customers with expert advice in all phases of product development.

We also use the latest CAD technology to develop the process steps in the mould and validate them using simulations, which we can present in a clear and comprehensible way on request.

We are also available worldwide to optimise your tools for stamping and forming processes to the latest state of the art, if required.

Range of services

- Advice on product development

- Tool technology consulting and process optimisation

- Tool conception and design taking into account economic and ecological aspects

- Simulation

Tool concepts

We build your tool

As a competent partner in all areas of sheet metal processing and special applications, our design engineers are already involved in the first phase of our customers’ product development if required. We develop the right tool concept according to the defined requirements and demands of our customers.

Our portfolio includes the following concepts and systems.

- Progressive dies

- Punching tools

- Complete cutting tools

- Levelling tools

- Embossing tools

- Thermoforming moulds

- Transfer tools

- Softtool tools

- Prototype tools

- Customised products on request